Automated greenhouses simulate the optimum climate conditions for maximum plant growth. A plant’s output can be maximized by maximizing photosynthesis. To achieve this, controlling many parameters with tight margins is necessary. By precisely controlling these three parameters, you can maximize the transpiration rate in the greenhouse, thereby maximizing photosynthesis. The result is healthier plants, greater output, and shorter growing times.

Automation and Robotics in Greenhouse Farming

Greenhouse Automation Parameters

- Temperature: Each plant species thrives at a different ideal temperature, but the idea is the same. In a greenhouse, the temperature should be set at the ideal level for the species. A too-hot or cold plant will not produce an ideal output. Monitoring the irrigation water temperature at the plant drain line is also important.

- Relative Humidity: Controlling humidity is crucial to the transpiration rate. A gradient of moisture levels must exist between the leaf and the air for transpiration since water is transferred from the leaves to the environment.

- Vapor Pressure Deficits (VPD): The optimal VPD can be achieved by controlling the greenhouse’s air temperature and humidity. Plants will typically thrive in an environment with a VPD between 0.8 and 0.95 kPa, depending on the type of species in the greenhouse.

- Ventilation: The greenhouse needs to be properly ventilated. Automating ventilation systems in greenhouses can help maintain optimal growing conditions by monitoring airflow.

- Carbon Dioxide (CO2): Keeping CO2 enrichment levels close to ambient air prevents the air exchanged through ventilation from diluting the CO2 present in the air. It is ultimately a matter of shorter nursery time and stronger, higher-quality plants that result from CO2 supplementation.

Reasons to Invest in an Automated Greenhouse

Creates and Maintains an Ideal Environment

Managing environmental factors like heat, humidity, light levels, and ventilation can be challenging. Automated controls alleviate much of the burden and challenge growers face managing every aspect of the environment. Your greenhouse system can be fully automated to keep your climate attuned to the needs of your crops without the need for constant monitoring and adjustments. Your greenhouse will be able to maintain a consistent and predictable growing environment by installing an automation system.

Reduces Energy Costs

Automation can reduce overall production costs, one of its biggest benefits. The long-term savings of an integrated automated system are well worth the initial capital costs. With so many options available, automation has become accessible to almost every grower, regardless of budget. A large number of growers are losing money due to inefficient energy use. While an automated system will ensure your systems work together as a team, it will save you money on production costs.

Combats Location Issues

Integrated automation systems can assist growers in climate-restricted locations. For example, floriculture growers supplying big box retailers cannot be restricted or miss deadlines because of a colder spring or lower light levels than expected. Likewise, garden centers need to ensure that quality products are available in spring and summer. With an automated system, you can grow your product on your terms, no matter what Mother Nature throws.

Optimize Human Resources

Control of plants is exclusively assigned to the central computer in an automated greenhouse. Therefore, operators will be asked to enter the required parameters and periodically verify that they are obtained methodically. Compared to non-centralized or manual control systems, this operation takes about 10 minutes daily. Since the central computerized system will alert operators only if anomalies occur, continuous monitoring of the plants will not be necessary.

In case you missed it: Robotic Bees for Pollination: Tiny Drones for Artificial Pollination in Agriculture, Pros, and Cons

Reduce Consumption of Water and Fertilizers

By automating irrigation and crop nutrition systems, significant water and fertilizing savings can be achieved, which leads to cost savings and reduced environmental impact. Using automated irrigation instruments to manage soil crops in an inert substrate can reduce water and fertilizer consumption by up to 25%, increasing productivity by 18%.

Reduce the Use of Pesticides

Better climate control and precise irrigation produce healthier plants in greenhouses. Healthy plants are less prone to diseases and insect infestations. Controlled environments reduce insect and pesticide consumption, according to growers.

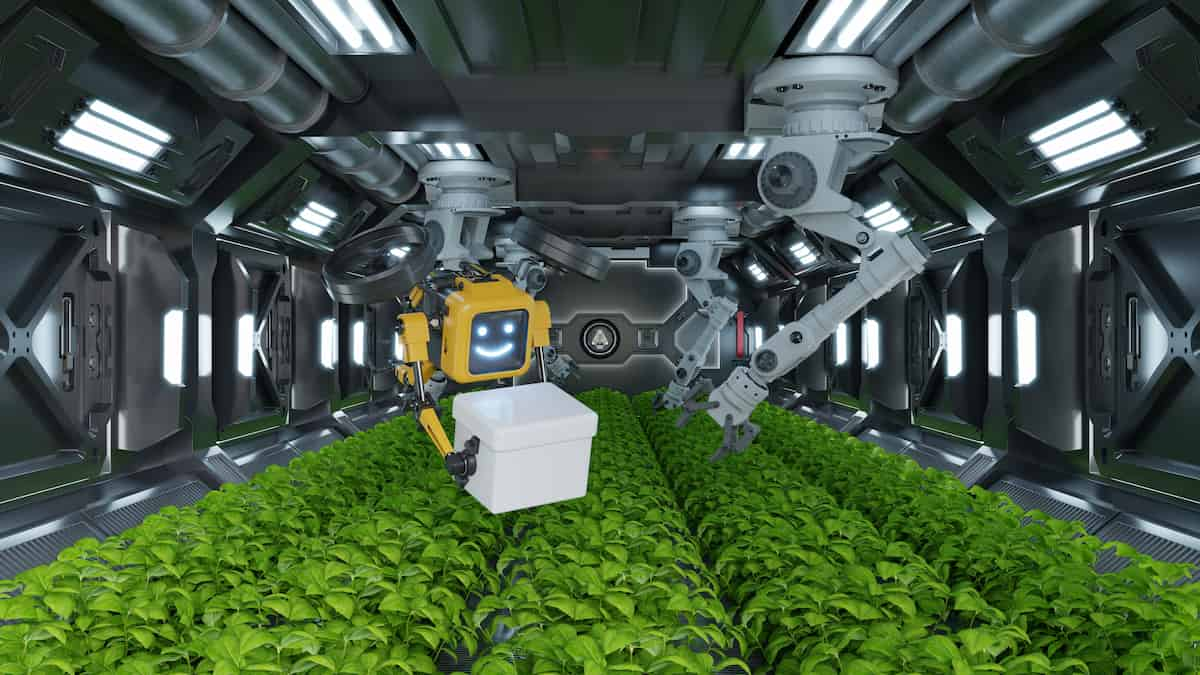

Robotics in Greenhouse

Year-round demand for quality produce is met by producing vegetables, fruits, and flowers in greenhouses. The greenhouse production sector is, however, very labor-intensive. Horticulture robots are about much more than merely replacing workers currently in short supply. Robots will eventually replace humans for some of these boring, repetitive tasks.

However, the real value will be in creating new business models. Robots already used to harvest produce in greenhouses will play an important role in collecting data. By introducing robotics into greenhouse farming, costs are halved, and labor is reduced by 80 percent. Some of the key innovations are:

Harvesting Robotic Arms

New harvesting systems for high-value crops are emerging with the help of machine vision tools and robotics. Several robotic arms can be extended for increased harvest speed, and an advanced 3D vision system can be used for identifying ripe fruits among leaves and stems. The system can also detect damaged or lost fruits using touch-sensitive terminals.

Automatic Conveyor and Material Handling Systems

Using rolling benches instead of stationary benches and growing directly on the ground can improve space efficiency by up to 30 percent. By improving airflow underneath the benches, workers can work at waist height rather than on the ground, and there is a reduced risk of plants getting humidity-related diseases.

Spacing Robots

By using robots alongside people, robots can perform dreaded manual labor tasks such as plant spacing safely. Due to their consistent spacing, robots can also increase plant quality by optimizing plant placement and reducing non-labor production costs, such as water, pesticides, herbicides, and fertilizers.

Farm Helper Robot to Remove Weeds

Weeding takes up about one-fifth of organic farmers’ time, so developing a robot to eliminate this chore was a key objective. Farmers can save time and energy by using these robots to complete arduous tasks. Plant losses can be reduced by spotting diseases or pests early on, reducing the need for pesticides.

In case you missed it: Organic Garden Pest Control: DYI Step-By-Step Guide

Conclusion

The greenhouse environment has a lot of variability and complexity due to bad weather. With automation in the greenhouse, you have full control over your greenhouse operations, and the more control you have, the better your crop will grow. Robotic systems are helping growers overcome problems created by a changing labor market and a shrinking pool of available farm workers.

- Feed Your Flock for Less: Top 10 Tips to Save on Chicken Feed

- Ultimate Guide to Ossabaw Island Hog: Breeding, Raising, Diet, and Care

- Hatching Answers: The Top 10 Reasons Your Chickens Aren’t Laying Eggs

- Eggs and Economics: Breaking Down the Cost of Raising Backyard Chickens

- Defend Your Greens: Proven Methods to Keep Iguanas Out of Your Garden

- Ultimate Guide to Cinnamon Queen Chicken: A Comprehensive Guide for Beginners

- Ultimate Guide to California Tan Chicken: Breeding, Raising, Diet, Egg-Production and Care

- Ultimate Guide to Marsh Daisy Chicken: Breeding, Raising, Diet, and Care

- 10 Types of Chicken Farming Businesses You Can Start for Profits